Advancing Pavement Defect Detection with AI and 3D Point Cloud Mapping

Pavement defect detection plays an important role in road maintenance, asset management, and long-term infrastructure planning. Traditional inspection methods rely heavily on manual visual checks or limited 2D images, which often miss depth information or fail to capture the true scale of the defect.

At GeoAI, we take a different approach. We combine 2D AI detection with high-accuracy LiDAR point clouds to produce a three-dimensional polygon map for every detected pavement defect. This workflow creates a more complete and measurable record of road surface conditions. It is perfect for digital twin integration, maintenance prioritization, and long-term pavement management.

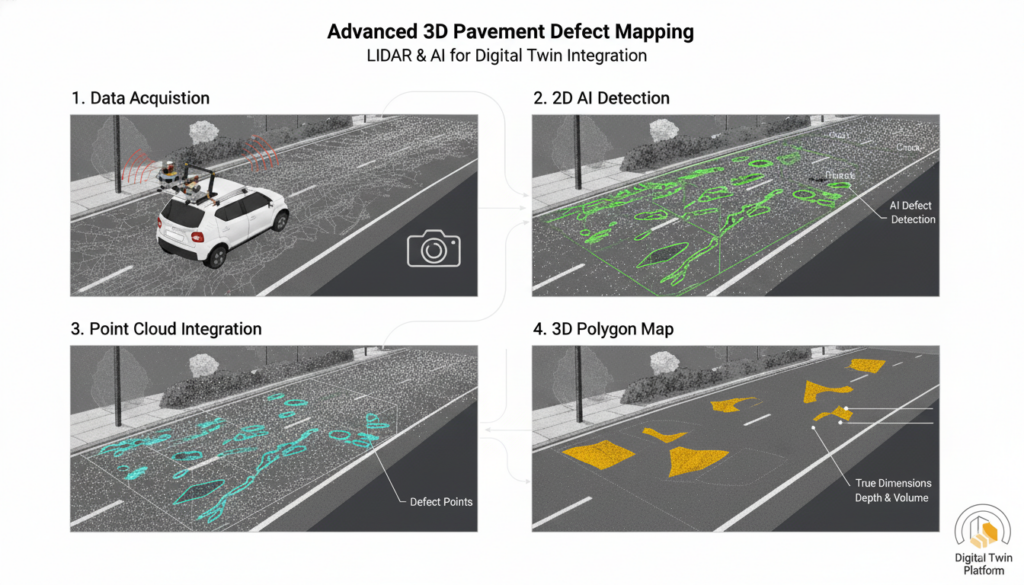

Our Workflow: From 2D AI Detection to 3D Polygon Mapping

We designed the workflow to take advantage of both image-based AI and the geometric accuracy of LiDAR. The process works in four main stages:

1. Pavement image capture

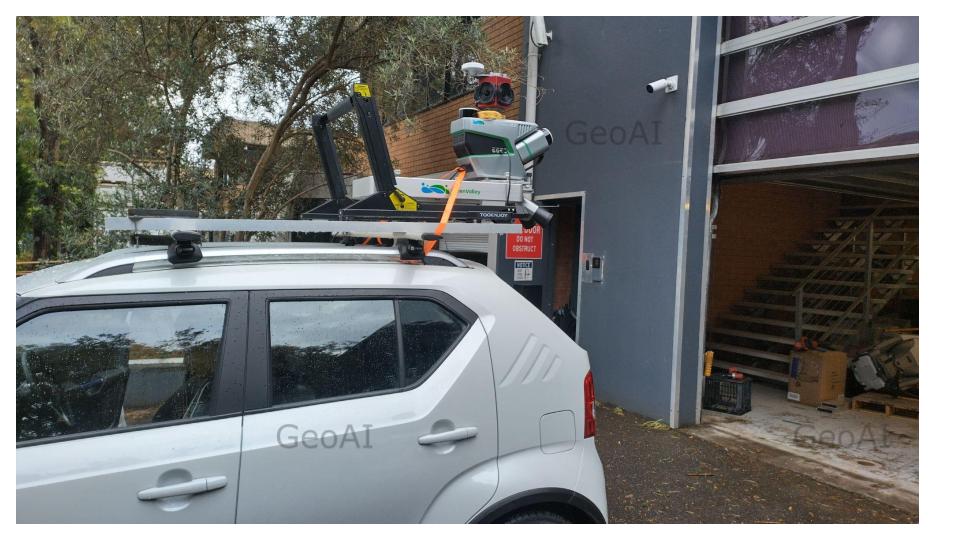

Using a mobile LiDAR system equipped with a panoramic 30 MP camera, we capture high-resolution road surface imagery while simultaneously collecting LiDAR data. The system supports:

- Up to 300 m range

- 1.28 million points/second (dual return)

- SLAM capabilities for GNSS-challenged environments

- Real-time data monitoring

This ensures that both the images and the point clouds are aligned and ready for AI analysis.

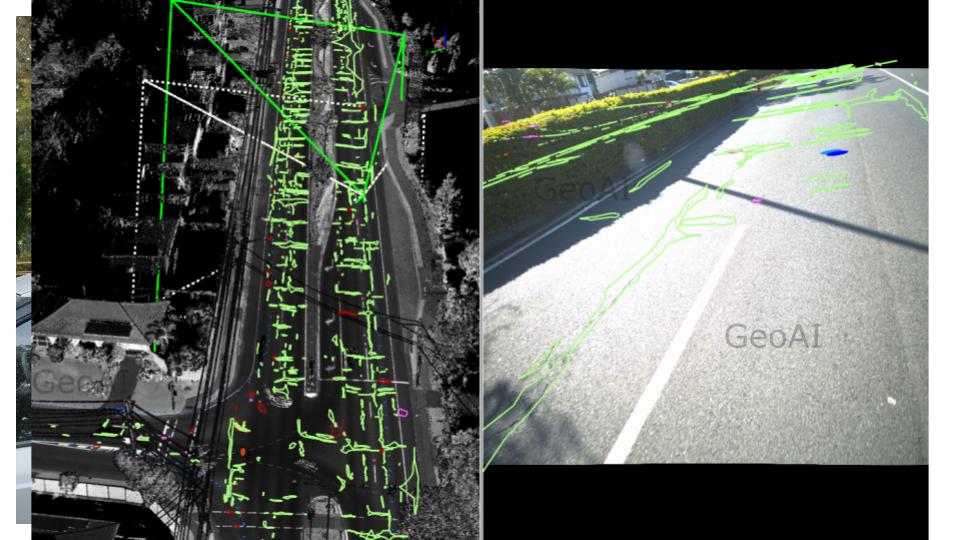

2. 2D AI detection of pavement defects

We apply deep learning models to the road surface images to detect common pavement defects such as:

- Cracks

- Potholes

- Raveling

- Edge failure

- Surface deformation

The AI model returns precise 2D bounding boxes and segmentation masks for each defect.

3. Mapping 2D detections into the LiDAR point cloud

The important step happens here. Instead of stopping at 2D detections, we project each identified defect into the LiDAR point cloud using camera calibration and pose information.

This means every defect is:

- Georeferenced

- Measurable in 3D

- Represented by an accurate polygon

- Linked to elevation and surface roughness

This step transforms a simple 2D detection into a spatially meaningful asset.

4. Generating 3D defect polygons

Once the defect pixels align with the point cloud, we extract only the points belonging to the defect area.

We then build a 3D polygon around the defect, capturing:

- True dimensions

- Depth and volume

- Surface roughness

- Road slope influence

These 3D defect polygons can be exported for engineering workflows or integrated directly into GeoAI’s digital twin platform.

Why This Approach Is Better

1. Higher accuracy with real geometry

Conventional 2D defect detection can only estimate size. Our point cloud–based workflow measures actual geometry with ≤ 5 cm absolute accuracy from the LiDAR system.

2. Detect depth and volume changes

Some defects, such as rutting or depressions, cannot be identified from 2D images alone. Mapping the defect into 3D reveals depth and shape, improving maintenance decisions.

3. Automated, scalable, and fast

Performing 1.28 million points per second and real-time AI processing enables rapid assessment of long highway corridors.

4. Easy integration with digital twins

The resulting 3D polygons fit directly into GeoAI’s digital twin ecosystem, allowing clients to:

- Visualize road defects in 3D

- Track defect progression over time

- Prioritize maintenance based on geometry

- Share accurate spatial reports with contractors or councils

5. Better documentation for asset lifecycle management

With georeferenced 3D defect data, asset managers gain a consistent and reproducible record of pavement condition across inspections.

Example Outputs

Our workflow produces:

- Raw LiDAR point clouds

- Classified pavement point clouds

- 2D segmentation results for each defect

- 3D polygon maps representing defect boundaries

- Depth and area measurements

- Road roughness indices

- GeoAI digital twin layers for visualization and monitoring

These outputs are tailored for road authorities, councils, infrastructure operators, and engineering consultants.

Applications of 3D Pavement Defect Mapping

Road Asset Management

Create digital inventories of cracks, potholes, and surface failures.

Maintenance Prioritization

Rank repairs by severity, depth, and risk.

Quality Control for New Construction

Verify new pavements or resurfacing projects using geometry-based measurements.

Digital Twin Integration

Visualize pavement deterioration in 3D over multiple inspection cycles.

AI-Driven Predictive Maintenance

Combine time-series data with AI to predict defect progression and optimize budgets.

Category List

- 3D Point Cloud

- Artificial Intelligence

- Asset Management

- Digital Twin

- Featured

- Hardware

- Knowledge Graph

- LiDAR

- News

- Site Monitoring

- Vegetation Monitoring

- Virtual Reality

Recent Post

- Asset Inventory Mapping with GeoAI: Complete Road Asset Capture Using Laser Scanning and Profiling

- Mobile Laser Scanner and Laser Profiler: Dual Approach to Road Surface Condition Surveys

- Edge Pavement Detection: Using LiDAR and AI for Road Asset Management

- What is Digital Surface Model (DSM)?

- Happy New Year 2026 from GeoAI

Frequently Asked Question (FAQ) about pavement defect detection

Cracks, potholes, raveling, rutting, edge failures, and various surface irregularities.

2D AI detects visual patterns, while LiDAR provides accurate geometry. Together, they create a precise 3D representation.

Using our mobile LiDAR system, the absolute accuracy is typically better than 5 cm.

Yes. The scanning system supports high-speed mobile mapping and long-range detection up to 300 meters.

Yes. They can be exported in standard formats (SHP, DXF, LAS) or visualized directly in GeoAI’s digital twin platform.