Asset Management using Artificial Intelligence: Cooling Tower Inspection

As part of asset management planning, a client aimed to understand the extent of the deterioration and develop a comprehensive maintenance plan. The object is Natural Draught Cooling Towers that were constructed in the early 1980s. After approximately 35 years of operation, signs of age-related deterioration have become apparent. The forecast was to continue operating the power station for another 20 years.

The cooling towers consist of cast-in-situ concrete shells mounted on a ring beam and supported by precast concrete “X” shaped columns. While the base section accessible from the hot water pond was in good condition, the upper portions of the shell had not been inspected since 2007.

Challenges in Asset Management Practices

The size and height of the cooling towers posed significant challenges for conventional inspection methods, such as scaffolding, making it difficult to conduct a thorough assessment. Additionally, representing the inspection results in a meaningful way for the client and consultants proved to be another obstacle due to the towers’ size and height.

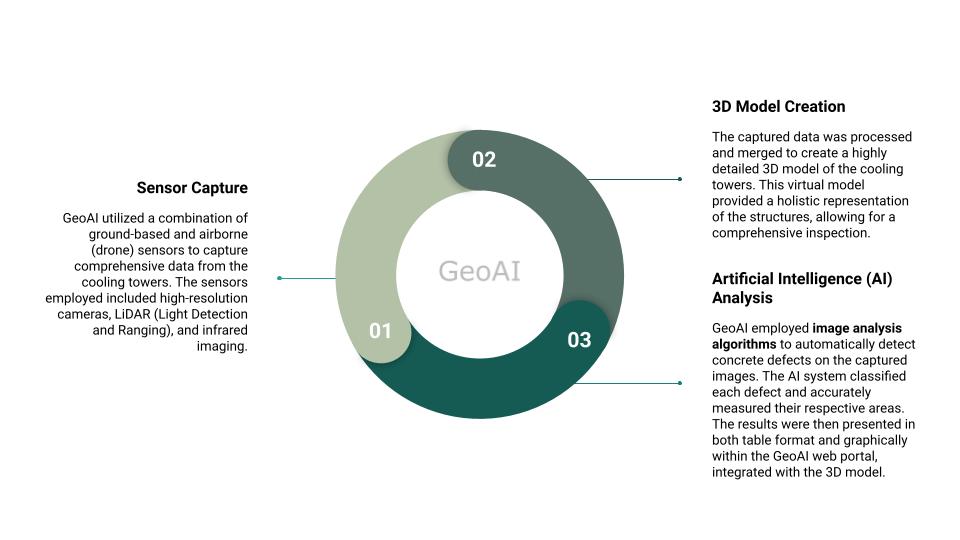

GeoAI Solution: AI-based Image and Point Cloud Data Processing

As an asset management company, GeoAI utilized ground based and drone sensors to capture the cooling tower data. By using the captured data, GeoAI created a 3D digital model to facilitate a comprehensive inspection. GeoAI use image analysis algorithm to automatically detect concrete defect on the captured images.

Benefit of the AI-powered Image Analysis for Asset Management

1. Enhanced Safety and Efficiency: By eliminating the need for conventional inspection methods such as scaffolding, GeoAI’s approach significantly improved safety and reduced the time required to assess the cooling towers as one of its asset management services. This resulted in cost savings and increased efficiency.

2. Comprehensive Data Analysis: The AI-powered image analysis provided a detailed understanding of the concrete defects, their classifications, and accurate measurements. The comprehensive data facilitated informed decision-making and precise planning for necessary repairs.

3. Intuitive Visualization: The 3D model and web portal integration allowed the client and consultants to visualize the inspection results effectively. The graphical representation facilitated clear communication, enabling stakeholders to understand the scope and severity of the identified defects.

GeoAI successfully addressed the challenges posed by the inspection of the cooling towers as an asset management consultant. Through the utilization of ground-based and airborne sensors, AI analysis, and intuitive visualization, GeoAI provided a comprehensive concrete spaling detection. The virtual inspection approach enhanced safety, improved data analysis, and facilitated informed decision-making for the maintenance and repair of the cooling towers.

Category List

- 3D Point Cloud

- Artificial Intelligence

- Asset Management

- Digital Twin

- Featured

- Hardware

- Knowledge Graph

- LiDAR

- News

- Site Monitoring

- Vegetation Monitoring

- Virtual Reality

Recent Post

- Pavement Defect Detection with GeoAI: Harnessing Laser Scanners and Profilers

- Asset Inventory Mapping with GeoAI: Complete Road Asset Capture Using Laser Scanning and Profiling

- Mobile Laser Scanner and Laser Profiler: Dual Approach to Road Surface Condition Surveys

- Edge Pavement Detection: Using LiDAR and AI for Road Asset Management

- What is Digital Surface Model (DSM)?