Material Tracking in Construction Project

In the dynamic world of construction, efficient material management is important for project success. Ensuring that the material is ready at the specific time, location, quantity, and quality is a goal for all project managers. Late delivery of construction material will make the project idle and lost their productivity. However, traditional material tracking effort often fall short, leading to delays and budget overruns. One of the primary challenges faced by construction teams is inaccurate material tracking, which has a direct impact on project timelines and costs. Thankfully, the solution to this challenge comes in the form of cutting-edge Laser Scanning Technology.

Challenge in Construction Material Tracking

Conventional material tracking methods are prone to inaccuracies and can result in wastage, delays, and budget overruns. Manual tracking and record-keeping processes are not only time-consuming but also susceptible to human error, making it difficult to maintain precise control over material inventory. Current material tracking system using Radio Frequency Identification (RFID) or barcode needs a manual tagging to each material. Other technology such as Global Positioning System (GPS) and Bluetooth Low Energy (BLE) requires additional installation to ensure network coverage.

Category List

- 3D Point Cloud

- Artificial Intelligence

- Asset Management

- Digital Twin

- Featured

- Hardware

- Knowledge Graph

- LiDAR

- News

- Site Monitoring

- Vegetation Monitoring

- Virtual Reality

Recent Post

- Photogrammetry vs Image Processing: What’s the Difference and How Are They Used?

- Soil Adjusted Vegetation Index (SAVI): Definition and Application

- NDWI (Normalized Difference Water Index): Identifying Water Bodies with Remote Sensing

- Construction Management in the Digital Era: How GeoAI Transforms Projects with Data Analytics and AI

- What is Near Infrared (NIR)?

Solution for Material Tracking System

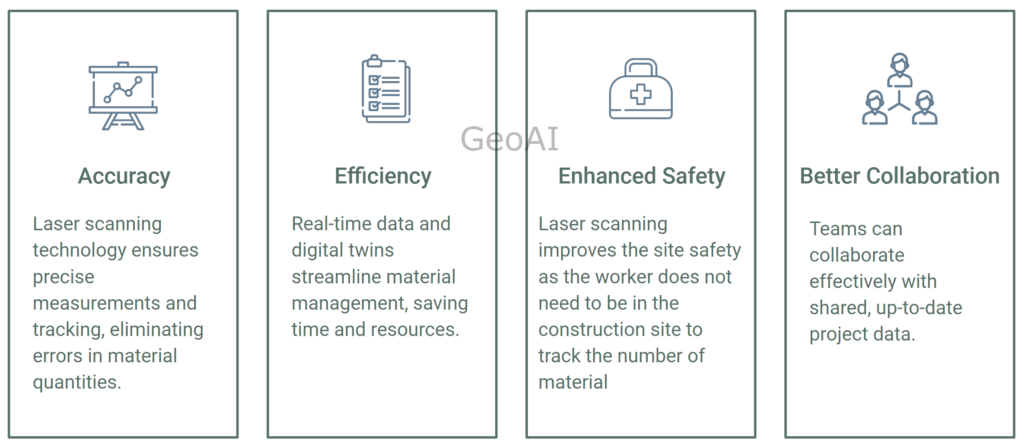

Laser Scanning Technology revolutionizes material tracking in construction projects. By employing laser scanners, construction teams can capture detailed 3D point cloud of the project site, creating a digital twin. Moreover, By extracting semantic information from the point cloud data, this digital representation enables accurate tracking of materials both for the prefabricated components and bulk material.

Outcome

Laser scanning technology enhances project efficiency by providing real-time visibility into material quantities and locations. As a result, it can reduced construction delays, minimized material wastage, and improved cost control. Projects are completed more swiftly and within budget, leading to higher client satisfaction.

Mobile Laser Scanning Benefit