What is Digital Twin Technology?

Many might feel confused about a new term called digital twin. So, what is the meaning of digital twin? Digital twin is a revolutionary concept, first introduced in the aircraft industry. It essentially creates a virtual replica of a real-world machine or operation, mirroring its behavior and characteristics through a digital model. This allows for meticulous simulation, testing, and optimization in the virtual world before impacting the physical counterpart, leading to reduced cost, enhanced efficiency, safety, and performance.

Benefit of Digital Twin Technology

After we know the digital twinning meaning, we might want to understand what is the benefit of digital twins for different industry including aircraft, manufacturing, and construction. Digital twins technology are vast and multifaceted, spanning across various industries. Here are some key benefits of digital twins:

Enhanced Design and Development:

- Accelerated innovation: Digital twins allow for virtual prototyping and testing of new designs, leading to faster development cycles and reduced time to market.

- Improved performance: By simulating various scenarios and optimizing parameters, digital twins can help designers create products with better performance and efficiency.

- Reduced risk and cost: Potential problems and bottlenecks can be identified and addressed early in the design phase. It can minimize risks and cost associated with physical prototyping and implementation.

Optimized Operation and Maintenance:

- Predictive maintenance: Digital twins can monitor equipment performance in real-time, enabling proactive maintenance and preventing costly breakdowns. It can also predict future maintenance need based on real-time data from the equipment.

- Optimized resource allocation: By simulating different operational scenarios, digital twins can help businesses optimize resource allocation and energy consumption.

- Improved decision-making: Real-time data and insights provided by digital twins help stakeholders make informed decisions about operations, maintenance, and optimization.

Enhanced Customer Experience:

- Personalized products: Digital twins enable the creation of personalized products and services tailored to individual customer needs.

- Improved customer service: By providing insights into product performance and usage, digital twins can help businesses offer better customer support and resolve issues faster.

- Enhanced training: Digital twins can be used to create realistic training simulations for employees, improving their skills and knowledge.

Category List

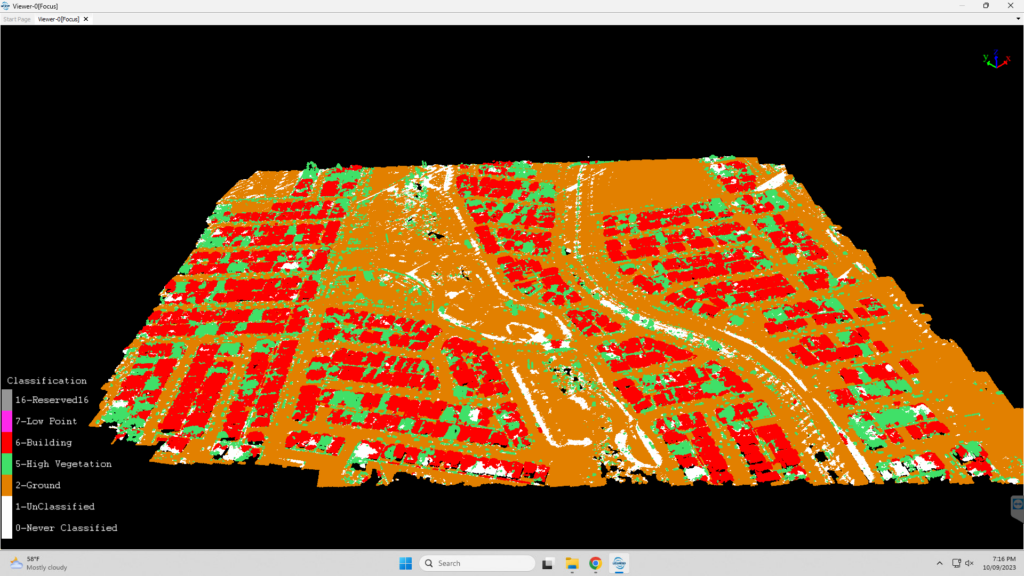

- 3D Point Cloud

- Artificial Intelligence

- Asset Management

- Digital Twin

- Featured

- Hardware

- Knowledge Graph

- LiDAR

- News

- Site Monitoring

- Vegetation Monitoring

- Virtual Reality

Recent Post

- Pavement Defect Detection with GeoAI: Harnessing Laser Scanners and Profilers

- Asset Inventory Mapping with GeoAI: Complete Road Asset Capture Using Laser Scanning and Profiling

- Mobile Laser Scanner and Laser Profiler: Dual Approach to Road Surface Condition Surveys

- Edge Pavement Detection: Using LiDAR and AI for Road Asset Management

- What is Digital Surface Model (DSM)?

Additional Benefits of Digital Twins

- Improved safety: Digital twins can be used to identify and mitigate potential safety hazards before they occur, leading to a safer work environment.

- Reduced environmental impact: By optimizing operations and reducing waste, digital twins can contribute to a more sustainable environment.

- Increased profitability: The benefits of improved efficiency, reduced costs, and enhanced customer satisfaction ultimately lead to increased profitability for businesses.

Overall, digital twins technology offer a transformative approach to designing, operating, and maintaining physical assets across various industries. They provide valuable insights, enable data-driven decision-making, and unlock new opportunities for innovation and efficiency.