Construction Management in the Digital Era: How GeoAI Transforms Projects with Data Analytics and AI

Managing construction projects in Australia has never been more challenging. Recent findings from Edith Cowan University show that over 77% of large-scale construction projects exceeding $200 million suffer delays of more than 40% and go over budget for more than 30%, with poor risk anticipation playing a major role. Some disruptions in construction project mainly caused by unstable supply chains, skilled labor shortages, and fluctuating material prices.

In today’s fast-paced construction industry, staying on time and on budget requires more than just project plans. It demands smart insights, real-time visibility, and proactive decision-making. That’s where GeoAI comes in. With these increasing risks, GeoAI empowers construction teams to stay ahead by:

- Identifying risks early through AI analytics

- Tracking delays using live field data

- Optimizing procurement with material forecasts

- Reducing rework and waste using 3D scanning validations

What is Construction Management?

Construction management is the planning of all aspects of a building project throughout its life cycle. Construction life cycle project starting from planning, procurement, construction, operation & maintenance, and demolition. Traditional methods rely heavily on manual monitoring, spreadsheets, and reactive problem-solving. But modern construction sites demand more.

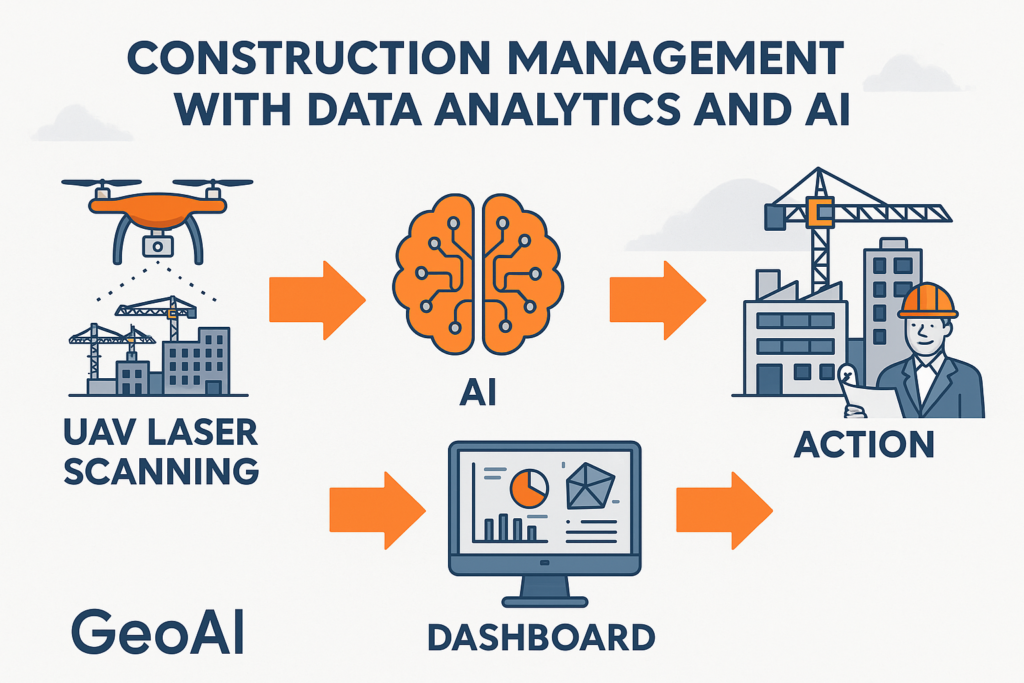

How GeoAI Enhances Construction Management

At GeoAI, we provide smart construction management solutions by integrating AI-driven analytics with advanced geospatial data capture tools. Our ecosystem helps project owners, engineers, and contractors make better decisions based on real-time site data. Here is some example of our work:

1. Real-Time Site Visibility with Laser Scanning

We deploy:

- UAV laser scanners for top-down mapping of large sites

- Mobile laser scanners for rapid walkthroughs throughout a large sites

- Handheld laser scanners for tight spaces

These technologies generate precise 3D point clouds of your construction environment. We do a scan-to-BIM procedure to enable accurate progress tracking, clash detection, and layout validation even in challenging terrains.

Actual bridge construction and its point cloud data to automate construction progress monitoring.

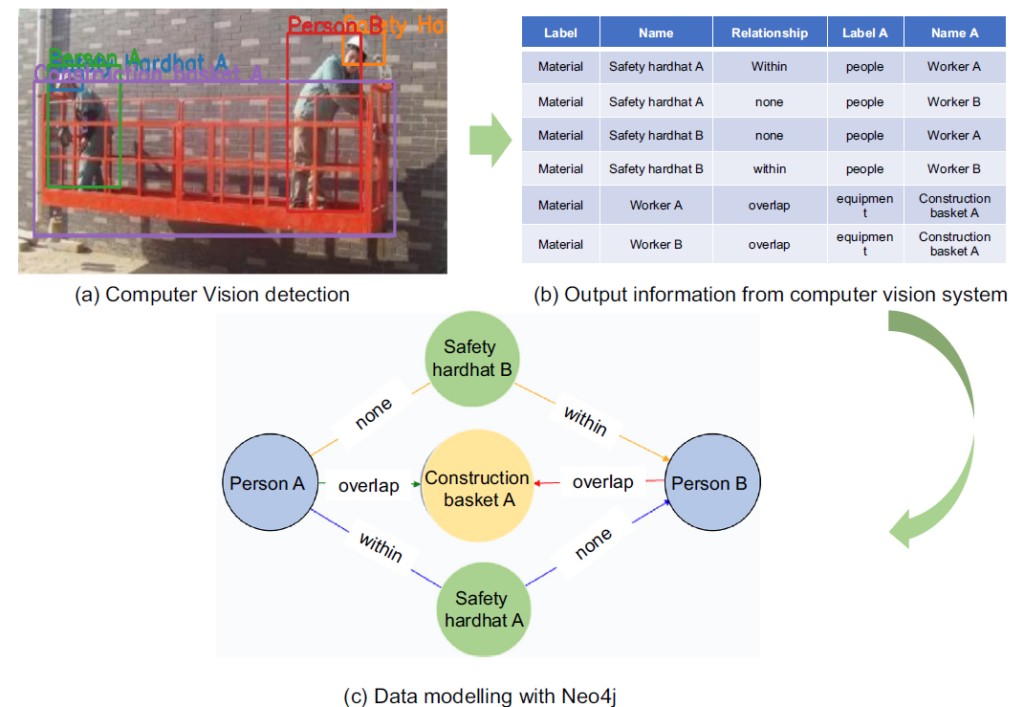

2. 360° Monitoring and Visual Intelligence

With 360° cameras, surveillance systems, and high-resolution imagery, we create a complete visual record of your site. This reduces disputes, improves documentation, and supports safety compliance.

From camera surveillance systems enhanced with AI-based computer vision, GeoAI can automatically extract critical insights that support safety, productivity, and compliance across construction sites. By combining real-time video streams with trained recognition models, the system can generate valuable data points, including:

- Automatic Worker Identification

Through facial detection and clothing-based patterns, the system can recognize individual workers on-site, track their movement - Equipment Identification and Tracking

AI models detect and classify machinery such as excavators, cranes, and trucks. This enables real-time asset monitoring, movement history, and equipment utilization analytics, helping teams reduce idle machinery and improve scheduling accuracy. - PPE (Personal Protective Equipment) Compliance Monitoring

The system continuously scans workers to verify compliance with PPE requirements, such as helmets, vests, gloves, and safety boots. Automated alerts can be triggered if a worker is found without the necessary gear, supporting proactive safety enforcement. - Detection of Hazardous Site Conditions

By analyzing video feeds, GeoAI can flag high-risk areas such as open excavations, blocked emergency exits, or unauthorized entry to danger zones. This aproach will allows site managers to intervene before incidents occur. - Measurement of Idle vs. Productive Time

The system quantifies labor efficiency by recognizing periods of active work versus inactivity for individual workers or groups. As a result, these insights support performance reviews, time tracking, and workforce optimization.

3. AI-Powered Analytics

Our intelligent platform leverages advanced AI algorithms and machine learning models to deliver actionable insights across every phase of construction. By continuously analyzing data from laser scanners, surveillance systems, and digital plans, GeoAI can:

- Detect On-Site Changes Instantly

The system compares live scans or imagery with your design models (e.g., BIM) to automatically flag deviations. This ensures that progress stays aligned with the schedule - Identify Schedule Delays in Real Time

By analyzing production data, labor activity, and equipment usage, the platform forecasts delays before they happen. Early warning systems notify managers of off-track tasks, allowing for proactive rescheduling and resource allocation. - Detect Structural or Visual Defects

Computer vision tools analyze concrete surfaces, joints, façade panels, and finishes to identify cracks or deformation. As a result, we can reduce reliance on manual inspection and increasing defect visibility. - Forecast Material Demand Accurately

Using production rates, installation trends, and inventory levels, GeoAI predicts upcoming material requirements. This minimizes over-ordering, reduces storage costs, and ensures materials arrive just in time, especially for large-scale or remote projects.

4. Customized Digital Twin Dashboards

GeoAI builds custom digital twin dashboards that integrate your BIM, sensor data, drone imagery, and project schedule into a single command center. Therefore, you can get this data from the comfort of your chair anywhere:

- Monitor Daily Progress

Track construction activities in real time and compare them with your planned schedule. - Visualize Site Changes in 2D and 3D

See up-to-date drone scans or laser data overlaid on your BIM to spot deviations quickly. - Track Materials and Inventory

Monitor what’s delivered, used, or delayed — all in one place to avoid shortages or waste. - Forecast Delays and Bottlenecks

AI analyzes trends to warn you of upcoming delays or resource conflicts. - Coordinate with Stakeholders

Share live data, visuals, and reports with your team, clients, and subcontractors for better alignment.

Category List

- 3D Point Cloud

- Artificial Intelligence

- Asset Management

- Digital Twin

- Featured

- Hardware

- Knowledge Graph

- LiDAR

- News

- Site Monitoring

- Vegetation Monitoring

- Virtual Reality

Recent Post

- Pavement Defect Detection with GeoAI: Harnessing Laser Scanners and Profilers

- Asset Inventory Mapping with GeoAI: Complete Road Asset Capture Using Laser Scanning and Profiling

- Mobile Laser Scanner and Laser Profiler: Dual Approach to Road Surface Condition Surveys

- Edge Pavement Detection: Using LiDAR and AI for Road Asset Management

- What is Digital Surface Model (DSM)?

Frequently Asked Question

A digital twin in construction is a virtual replica of a physical project site, updated in real time using data from sensors, drones, and BIM. It helps project teams monitor progress, detect issues, and make data-driven decisions remotely.

AI enhances construction by forecasting delays, detecting safety risks, analyzing labor productivity, and optimizing material use. It turns complex site data into clear insights that reduce cost overruns and project delays.

GeoAI integrates data from UAV and handheld laser scanners, 360° and surveillance cameras, IoT sensors, BIM files, and scheduling tools. This enables a comprehensive view of your project in real time.

Absolutely. GeoAI’s digital twin platform is scalable and has been used on both vertical buildings and long-span infrastructure like highways, tunnels, and rail networks. It supports coordination across complex teams and schedules.

📞 Let’s Automate Construction Management Assessment with GeoAI

Contact GeoAI today for tailored construction management or other site monitoring services.

📧 admin@geoai.au

🌐 geoai.au

📍 34-36 Byrnes St, Botany NSW 2019